ONE LOOK AT THE LATEST WILBUR watch tells you quite a bit about its designer, Jason Wilbur. Unorthodox, uncompromising and completely unexpected, Wilbur invaded the world of watch creation with a bang more than a decade ago when one of his earliest wrist-borne designs rocketed to horological orbit with a Grand Prix d’Horlogerie de Geneve (GPHG) nomination.

Now the primary force behind the LEO, the newest watch from California-based WILBUR Watches, Jason Wilbur remains as untraditional as ever with a lineup of technically astute avant- garde timekeepers that enthrall certain collectors and send others running back to velvet-lined showcases.

As WILBUR chief designer, Wilbur doesn’t seek to make a watch built to meet existing expectations. He prefers to create new expectations by designing for the future. And if those designs step outside of current horology, he’s fine with that.

“I want to innovate in terms of design and architecture,” Wilbur explains. “Innovating within the silo of traditional mechanical watch drive-trains is a far second place for me.”

Calling himself a ‘forward scout’ for the watch industry, Wilbur designs watches he wants to wear.

“I want to use the valuable real estate on my wrist to express myself,” explains Wilbur. “I don’t want to put something on my body that is simply a tool or an extension of my phone, or even worse, a boring statement. That’s just me.” (For more details about Jason Wilbur’s design process and his vision for WILBUR Watches, see our in-depth conversation later in this post.)

The LEO

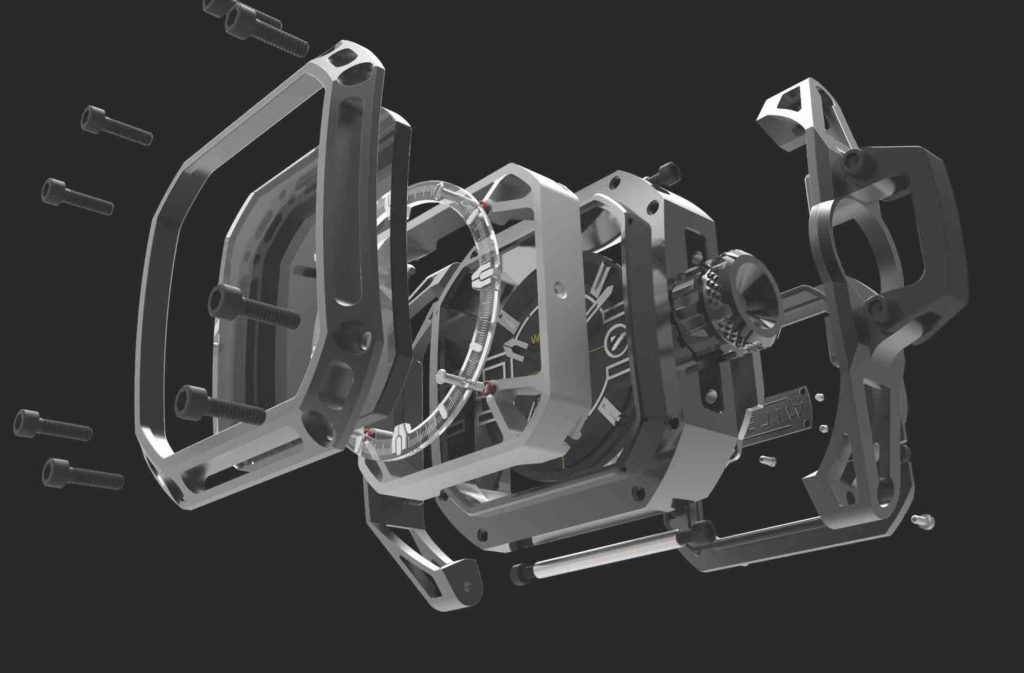

There’s nothing boring about the LEO, the latest WILBUR design. While the round-cased LEO rests on the wrist like a traditional watch, its multi-part titanium case does not frame the expected hour, minute and seconds hands. The LEO instead displays the time in an unusual manner on a dial that, as we’ve noted previously, looks like a satellite tumbling its way around Earth’s orbit.

The LEO’s extraterrestrial puzzle shows its wearer the current hour in digital form using a jump-hour display. And while this sort of digital display can be found within a few Swiss watchmaker collections, Wilbur’s unusual method of creating the hour digit is a world premiere, as devised with famed Swiss movement engineering company Concepto.

Wilbur couldn’t simply add a traditional jump hour to the other- worldly LEO. Instead, he devised a symbolic mash-up to perform the task of displaying the hour.

Whereas standard jump-hour digits are just numerals, the hour digit that appears in the LEO’s central aperture is actually a meeting of two otherwise indecipherable symbols.

Two sapphire disks, one clear and one brushed black, rotate twice a day on either side of the hour display. When they meet, those ‘alien’ symbols form the correct hour digit at the dial’s center.

To display the minutes and the seconds, simply note the two fixed bridges, which double as hands. Each points to the respec- tive time, with seconds indicated at the top of the dial and minutes appearing at the 6 o’clock position.

As we’ve noted in our earlier descriptions of the LEO, Wilbur spent seven years finalizing the LEO. The idea for the display however spent decades churning around in Wilbur’s brain.

“I wanted to create something that sprang from learning in my youth about the Roswell incident with all its alien stuff,” he recalls.

The appearance of cryptic symbols on twisted metal at the New Mexico ‘alien’ site sparked Wilbur to create his own symbols as a sort of WILBUR secret language.

“No one on Earth who saw those pieces would know what the symbols mean. So I created my own code. On the watch the hours come together with those coded symbols,” Wilbur explains.

The newest LEO, the LEO JW1.3 Firefly (above), teams DLC gunmetal titanium with silver and black dial components and ‘toxic yellow’ numerals. The limited edition of twenty-five watches ($36,500) joins the two existing LEO models.

These include the LEO JW1.2, with titanium and silver, gray and black components with white numerals ($36,500) and the blue-tinted debut model, JW.1.1 ($32,500).

These include the LEO JW1.2, with titanium and silver, gray and black components with white numerals ($36,500) and the blue-tinted debut model, JW.1.1 ($32,500).

The EXP

Wilbur notes that the LEO series is WILBUR’s primary High Concept model. To complement the LEO, Wilbur has created a deep selection of eight-sided EXP models, which he calls Daily Drivers.

Like the LEO, the EXP also offer collectors an unusually open- worked, architectural design, but with a movement based on an existing Swiss automatic caliber that WILBUR customizes and finishes to a higher standard.

The EXP echoes an automotive chassis, with what appears to be an engine suspended in air. Here, chapter rings float above a semi- transparent dial to create a true three-dimensional time sculpture for the wrist.

The 41.5mm open-worked, three-hand watch (with date) is available in a wide selection of case metals and colors, including ceramic and titanium, ceramic and anthracite DLC, ceramic and a gold alloy with black DLC. Prices start at $4,500.

Each option can be paired with an equally broad selection of colorful silicone straps, all of which can be quickly changed by the wearer.

One model, the EXP C-1, adds a bit of luxury to the series with a black ceramic case and a customized gold alloy lugs and bezel.

“We fell in love with a set of champagne gold wheels on a Porsche GT2 and set out to replicate the color,” explains Wilbur. “We wanted a modern and futuristic gold not a traditional gold, so we developed our own.”

iW Interview:

Jason Wilbur, Founder WILBUR Watches

How does your approach to watchmaking differ when compared to traditional watchmakers?

I’m an industrial designer, not a watchmaker. I am even part engineer, artist, explorer and risk taker.

Traditional watchmakers are craftspeople. They are often limited by the tools they use because of the traditional rules of watchmaking, or they focus on making everything by hand. Therefore, creativity and advanced manufacturing techniques or design tools take second place to making everything by hand.

That’s fine, but that is craft, not design, not art, and not WILBUR. Creating a machine with character is more important to me than inventing a new type of escapement. I touch every part of the watch just like a watchmaker, but I will use any advanced manufacturing technique or material to achieve my design. I will not let the tools define the outcome. I have only two limits I put on myself that I share with traditional watchmakers: My pieces must be mechanical and they must tell time.

I want to innovate in terms of design and architecture. This is more important to me than innovating within the silo of traditional mechanical watch drive-trains.

How does WILBUR fit in with the expanding group of U.S.-based watch companies?

I look at myself as the forward scout of the industry. I don’t mind wandering into uncharted territory for the sake of futuristic exploration. Most American watch brands are the opposite of this.

WILBUR is advanced American design meets Swiss watch- making. We don’t really feel like we “fit in” anywhere. U.S.-based watch companies are growing and I am excited for them, but they tend to focus on fairly traditional design with many of the products competing on price. When you do that, there’s not a lot of room for innovation. We want to be THE luxury American watch brand.

Is it difficult to source components in the United States?

No. It’s easy to source components. But, they are expensive and the manufacturers are spread out all over the country. It is much easier, cheaper, faster to do everything in Switzerland.

Our LEO is built 100% in Switzerland. The EXP is made with Swiss and U.S. parts and assembled in United States. The Launch Edition is sold out and since it was a limited edition we will not be continuing that line.

Making watches in the U.S. is not our brand focus; designing them and inventing them in the U.S. is our focus. All our watches in the future will be made through our partners in Switzerland.

Nobody cared that we made the watches in the U.S. They actually shunned us for it. I actually had retailers here tell me they weren’t interested in the watches because they were made in the U.S. and not in Switzerland.

Funny, they are happy to do business in this country, but they won’t support things made here.

Is it also hard to find the watchmakers you need?

No. There are plenty of talented watchmakers here in the United States, but they are used to simpler watches. However, once they get used to WILBUR watches they do amazingly well with them.

How do you first consider creating a new WILBUR watch design? What is your own design process?

I am sketching all the time. I am always coming up with new ideas for time displays or general watch architecture. Sometimes they come to me in dreams. That’s why I say WILBUR is “Dreams of machines.”

Once I have sketched the basic concept I will start to build the watch in CAD / Solidworks. This way I can start to implement the real-world engineering of the watch and set the stage for the serious engineering to take place.

During this phase I do a lot of 3-D printing of the case and straps to make adjustments to size and ergonomics and overall proportions. I create a lot of concepts, but most don’t see the light of day. I think exploration is the key to creative innovation. So I make a lot of concepts before I decide what to produce.

“We are not Tiffany & Co, we are NASA with an attitude.”

How has your own history as a designer in other areas influenced your watch work at WILBUR?

I’ve spent a majority of my life making things that people told me at first were impossible. So I know that when someone says some- thing can’t happen, it’s all the more reason for me to do it. I’m motivated by challenges, not by guarantees.

For example, during my time in Advanced Design for Honda, the purpose was to seek out new ideas, not refine old ones. So I do that now with the WILBUR watch brand. I also use a lot of the same advanced CAD and research and development techniques and methods that I used to create concept cars and vehicles.

Everything from modern racing chassis architecture to futuristic drone flight systems inspire the design language of the WILBUR brand. We are not gold and diamonds, we are carbon and titanium nitrate. We are not Tiffany & Co, we are NASA with an attitude.

Are you creating art or a piece of high-technology?

I spent my whole career on high-tech programs. This is my art. This is mechanical expression.

WILBUR is mechanical sculpture that happens to tell time. It’s sculpture with attitude and a soul.

Merging advanced design with old-school mechanical time- keeping technology is what this is all about for me. I’m more concerned with emotional value than with high-tech features.

WILBUR is frankly an escape from certain technologies. Analog will set you free.

Another note regarding this: I believe I want to use the valuable real estate on my wrist to express myself. I don’t want to put something on my body that is simply a tool or an extension of my phone, or even worse a boring statement. That’s just me.

How does the more complex LEO series differ from the ongoing EXP?

The WILBUR brand has two product focal points: We have “Daily Drivers” like the EXP, and then we have the “High-Concept” watches like the LEO.

The LEO is the first in our lineup that has an in-house movement, which we call the WILBUR Engine One. The High Concept line focuses on unique time displays and requires serious research and development to get to production.

Our Daily Drivers currently have in-house modified and regulated movements that have stock movement gear trains and retain most of their architecture in order to make a highly reliable watch with the spirit of our high concept watches, but more for daily wear. And while these are also limited edition watches, production is such that the Daily Drivers are priced at more of an entry level.

Why should a collector look to purchasing a LEO or another Wilbur watch instead of a watch from a high-profile Swiss or German watch with a similar price?

My customers are leaders. They are trendsetters and people who trust themselves and typically have a progressive mindset when it comes to timepieces. They love my watches and the design first – before they care about anything else. They respect the fact that I design my timepieces myself and I have old-school values when it comes to customer service.

My watches are derived from nothing but my own ideas and I don’t do focus groups. I built this company from nothing but pure will and grit, which means that my products are made with love and an unmatched attention to creativity and design.

But it also means that my customers understand that by buying into the WILBUR brand, they are buying into a journey that will be unlike anything else.

My brand is me. I design everything from the retail watch stands and displays to the shipping box stickers. I’m not a huge Swiss corporation, so I personally thank every single person who buys my watches. I also do all the WILBUR retailer training in person. Someone who heavily values the brand profile of being Swiss or German is not going to be buying a WILBUR watch and I wouldn’t want them to.

I don’t want people buying my watch simply because that’s what someone else told them to do. The WILBUR brand has staying power and I’m here to build a legacy, not a project. Real collectors that take the time to get to know me and the brand understand this and become supporters.

Do you plan to build new versions of the LEO model in the near future?

We have several new projects in development at the moment, one may be another version of the LEO or it could be something entirely new altogether. You never know! The R&D machine never sleeps!

Will WILBUR look beyond watches at some point, venturing into other products?

Possibly. But for the time being I’m focused on watches. I don’t understand my fascination with making watches.

I am obsessed and cannot stop. If I one day finally understand it, it means I am no longer creating things with soul, and that’s the day I’ll quit…and do something else.